Winter is the time to thin forests especially for the Pacific Ocean side of Japan. During winter, trees minimize their intake of fluid in order to avoid freezing of their arterial: for trees, frozen arterial = bursting of the trunk = death. Consequently, they are literally dried, but alive. Less moisture in their cells means to cut less heavier and comparatively smoother trees. “Smoother?” Yeah. For example, cutting cedars is definitely easier all year round than cypresses whose texture is, I would say, more persistent for saws to eat into. For a same species, dryer a tree is, easier for saw tooth to furrow the trunk. Winter in Kanagawa Prefecture is cold and dry. So we thin the cold forest now as it’s easier, you see?

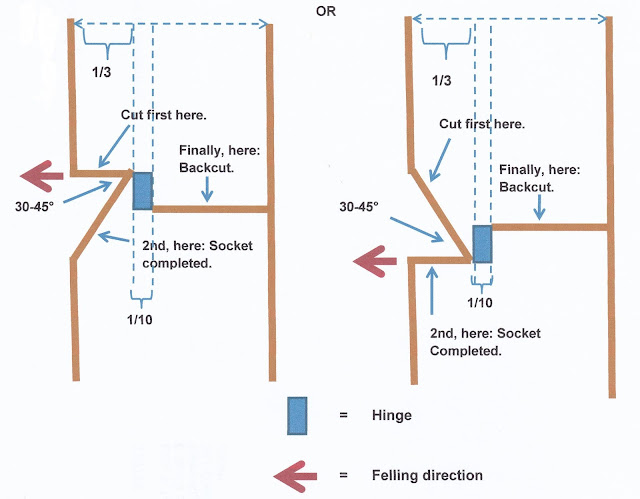

You may think cutting dead and desiccated trees during much warmer time should be easier. Er, no. It’s tricky to cut down dead trees which are completely dried. When we cut tree, we first create a socket facing to the exact direction for the felling. I’ve heard the Western style for a socket is in this way:

In contrast, Japanese way is this:

|

| Actually

created socket. This tree would fall into the direction of the handle of a fan. |

After creating the socket, we make a backcut that should never reach to the socket. Roughly 1/10 of a diameter of a trunk is intentionally left intact that could keep the tree standing somehow. This part is called “Hinge” that is VERY important. After completing a backcut, we either hammer wedges in the backcut, or pull a rope prepared before creating a socket, in this way:

|

| Actual setting of the rope work |

After finishing the backcut, wedges erode the power of hinge, or we pull the cable for the tree, and the tree would fell to the direction its socket faces. During the operation, desiccated and dead trees could act unexpectedly more than dry but living trees. They may snap in the middle through cutting the socket and backcut. It is extremely difficult to predict which part of a trunk, bough, and/or root would collapse. If the broken part fell over our head, we are killed. Even if a dead and dried tree does not break in the middle, it’s difficult to control the direction of the felling. We don’t know if the hinge works while cutting. Such maneuver is better to be left to pros with heavy machinery. So, we volunteers in Japan thin the forest of living but dry trees when the tree can maintain its clinging power of the hinge to some extent, while a saw can eat into the trunk relatively easily.

|

| And we are pulling … |

|

| After

a tree fell, if the hinge worked, the cut should be looked like this. The hinge was torn off. It means there was a resistance to fell down; i.e. we had time to escape. |

Volunteers are supposed to operate with handsaws. But forests in Japan these days have often been neglected for a long time. They missed the ideal timing of thinning, and we face a mess in a forest with many many malnourished trees to be thinned. Limiting handsaws for ourselves is impractical. Chainsaws are often used to tackle the issue. Lovers Organization of Niiharu Citizen Forest 新治市民の森愛護会 has several chainsaws that are heavily used. A couple of them have reached its replacement time. Recently, the Lovers bought shining new chainsaws, the latest STIHL-made. At the moment, the Chairman and the Vice-Chairman of the Organization do not allow us to use them yet in the fields. (Ohhhhhhhhhhhhh) But we had a sort of workshop how to handle them.

|

| Niiharu

Lovers’ old gadgets. We have several more larger ones + new machines as well. |

A guy from the agent for STIHL told us, “So, this latest model you purchased has a computer tip in their body. It can learn how you guys use them, and adjust accordingly the usage of gas and chain oil at optimum. It makes the problem of smog emitted from the chainsaw reduced. This is a novel approach for forestry in Japan!” Oh, is that so, I thought. No wonder Japan received F-grade for COP25 last month. The guy from STIHL continued, “I warn you. Please do not rev up the machine more than once. It regards such move as a sign something wrong, and would automatically stop operating. Re-ignite the engine might need re-programming in our factory that is surely inconvenient for all of us, you know.” Wow. So, the saw will start quite easily and stably, without much need for rev-ups. Good. “It also operates in lower noise.” Hmmmm, this is a very German machine …. Now we Lovers are looking forward the day when the OK sign comes for our new toy … Heck, in any case I think I’m standing at the end of the line for the new machine. I have to wait while my seniors have completed their turn to put their hands on the new troop of the chainsaw … patient ... Having said that, the Organization let me attend a training session to obtain legally endorsed certificate to operate chainsaws. I report you my experience during the session next week!

|

| Our

lecturer explains the design of saw tooth for chainsaws. |

If you find an environmental issues

in Kanagawa Prefecture, please make a contact with Kanagawa Natural Environment Conservation

Center 神奈川県自然環境保全センター

657 Nanasawa, Atsugi City, 243-0121 〒243-0121 厚木市七沢657

Phone: 046-248-0323

You can send an enquiry to them by clicking the

bottom line of their homepage at http://www.pref.kanagawa.jp/div/1644/

No comments:

Post a Comment